Leader in 3D Printing Services

Upload your CAD file for instant quotes across SLA, SLS, FDM, and MJF 3D printing and get overnight delivery. Join 4,600+ engineers who trust us.

Your CAD uploads are protected as per ISO/IEC 27001

Our 3D Printing Services

Experience India's widest and largest 3D printing services, with free online instant quotations.

SLA 3D Printing Services

SLA - Stereolithography

SLA 3D printing offers fast and precise parts with smooth surface finishes and exceptional detail, making it ideal for rapid prototyping and showcase models.

Materials: ABS, Clear PC-Like

Max Print Size: up to 1200mm

Delivery within 24 Hours

SLS 3D PRINTING SERVICES

SLS - Selective Laser Sintering

SLS 3D printing delivers nylon-grade parts, making it ideal for rapid prototyping, end-use functional models and low-batch production.

Materials: Nylon PA12, PA12 + Glass Filled

Max Print Size: up to 450mm

Delivery within 3 days

DLP 3D PRINTING SERVICES

DLP - Digital Light Processing

When design becomes challenging, 3D Systems Figure 4 delivers ultra-thin production grade parts within hours.

Materials: Pro-Black 10, Rubber65A

Max Print Size: up to 200mm

Delivery within hours

FDM 3D PRINTING SERVICE

FDM - Fused Deposition Modeling

FDM 3D printing offers economical prototyping producing strong, durable parts using a variety of filament materials.

Materias: PLA, ABS, TPU, PETG, PC

Max Print Size: up to 500mm

Same day delivery

HP MJF 3D PRINTING SERVICES

HP MJF - Multi Jet Fusion

MJF delivers nylon PA12 end-use parts, which are bio-compatible and well suited for functional rapid prototyping.

Materials: PA12 Nylon (Greyish Black)

Max Print Size: up to 250mm

Delivery within 3 days

3D Scanning & Product Design

3D Scanning & Modeling

Our expert CAD engineers turn your concepts into precise, production‑ready designs—bringing your ideas to life with accuracy and speed.

Simple Part Modifications

Designing products from concepts

Reverse Engineering Services (3D Scanning)

Painting and Finishing

In-house Post Process

Get exceptional finishes and precise RAL color matching, ensuring your parts look exactly as you imagined.

Automotive grade paint booth facility

Finishes: Matte, Glossy, SoftTouch

Delivery within 48 Hours

Industry-Focused 3D Printing Solutions

Customized 3D printing services for automotive, aerospace, defense, healthcare, and more.

EV Battery Management System

EV Automotive

EV Charging Stations

Interior and Exterior Components

EV Cell Holder 3D Printing

2W/4W Automotive

Assembly Jigs & Assembly

Automotive & Robotics

Nylon SLS 3D Printing Services

Aerospace & Defense

Aerospace & Defense

Representation Model

Unmanned UAV 3D Printing

Aerospace & Defense

Canopies, Rubber Pads

Aerospace & Defence

Bio-Compatible Enclosures

Healthcare & Medical

Anatomical models for surgical planning

Healthcare & Medical

Bio Surgical guides

Healthcare & Medical

Industrial Grade Jigs & Fixture

Manufacturing & Tooling

Low Batch Production

Manufacturing & Tooling

Rapid Prototyping

Manufacturing & Tooling

Custom insoles and midsoles

Footwear

Toys & Action Figures 3D Printing

Consumer Products

Customized Home Decor

Consumer Products

Scale models of buildings

Architecture & Construction

Props, Sets and costumes

Film & Entertainment

EV Battery Management System

EV Automotive

EV Charging Stations

Interior and Exterior Components

EV Cell Holder 3D Printing

2W/4W Automotive

Assembly Jigs & Assembly

Automotive & Robotics

Nylon SLS 3D Printing Services

Aerospace & Defense

Aerospace & Defense

Representation Model

Unmanned UAV 3D Printing

Aerospace & Defense

Canopies, Rubber Pads

Aerospace & Defence

Bio-Compatible Enclosures

Healthcare & Medical

Anatomical models for surgical planning

Healthcare & Medical

Bio Surgical guides

Healthcare & Medical

Industrial Grade Jigs & Fixture

Manufacturing & Tooling

Low Batch Production

Manufacturing & Tooling

Rapid Prototyping

Manufacturing & Tooling

Custom insoles and midsoles

Footwear

Toys & Action Figures 3D Printing

Consumer Products

Customized Home Decor

Consumer Products

Scale models of buildings

Architecture & Construction

Props, Sets and costumes

Film & Entertainment

EV Battery Management System

EV Automotive

EV Charging Stations

Interior and Exterior Components

EV Cell Holder 3D Printing

2W/4W Automotive

Assembly Jigs & Assembly

Automotive & Robotics

Nylon SLS 3D Printing Services

Aerospace & Defense

Aerospace & Defense

Representation Model

Unmanned UAV 3D Printing

Aerospace & Defense

Canopies, Rubber Pads

Aerospace & Defence

Bio-Compatible Enclosures

Healthcare & Medical

Anatomical models for surgical planning

Healthcare & Medical

Bio Surgical guides

Healthcare & Medical

Industrial Grade Jigs & Fixture

Manufacturing & Tooling

Low Batch Production

Manufacturing & Tooling

Rapid Prototyping

Manufacturing & Tooling

Custom insoles and midsoles

Footwear

Toys & Action Figures 3D Printing

Consumer Products

Customized Home Decor

Consumer Products

Scale models of buildings

Architecture & Construction

Props, Sets and costumes

Film & Entertainment

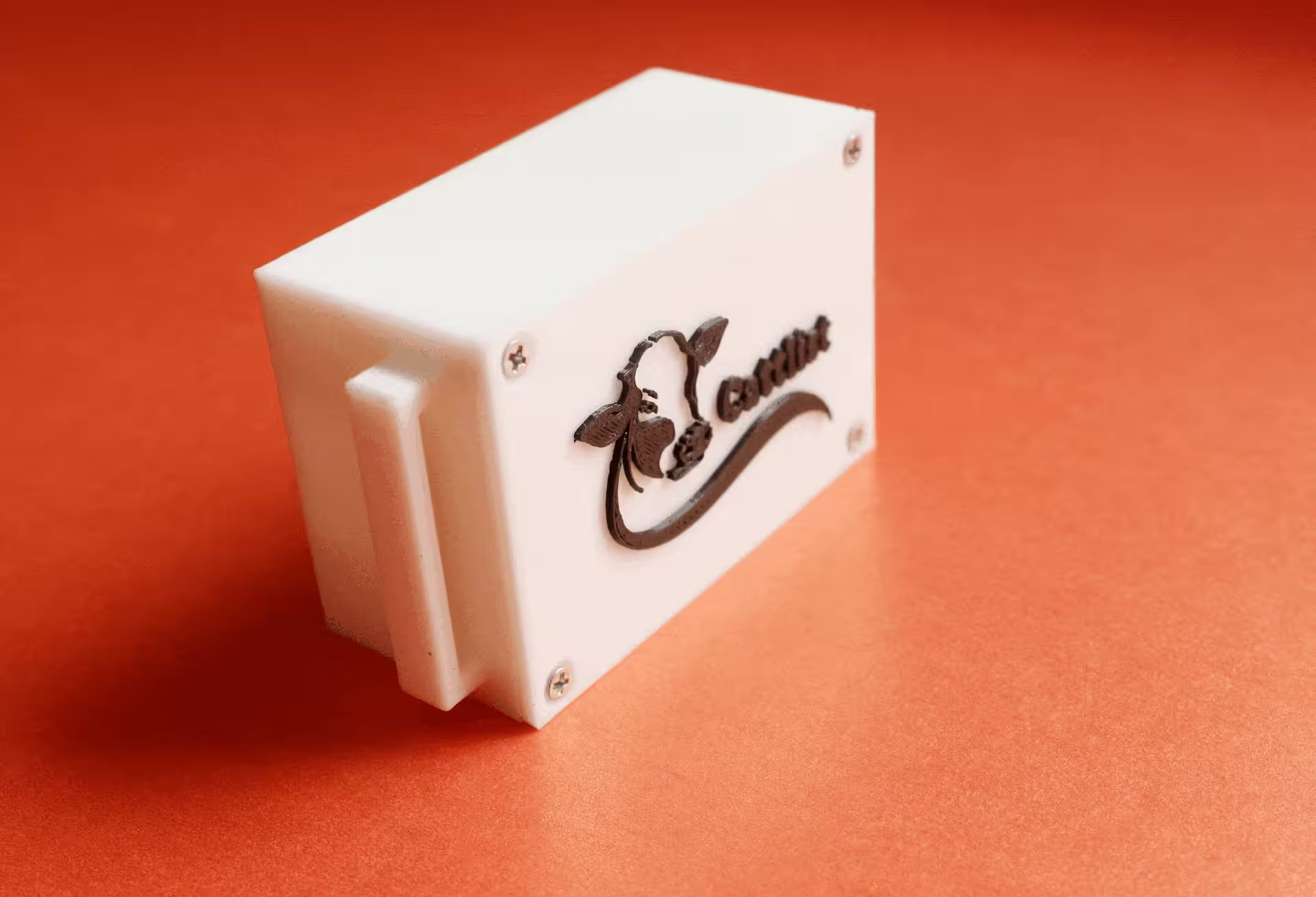

Outputs that speaks for itself

These works exemplify our expertise in delivering high-performance, customized 3D printed parts that meet industry standards delivered under tightest of timelines.

SLA-ABS

SLA-Clear

SLS-Nylon

FDM

Production-grade

Low-Batch

MJF

3D Scanning

Trusted by Industry Leaders Nationwide

From top brands to future icons, we help turn bold ideas into reality.

Meet Makenica®

3D Printing Since 2016

Founded by passionate makers, Makenica grew from firsthand manufacturing challenges into a mission—empowering the next generation of makers with the tools, support, and transparency we once needed.

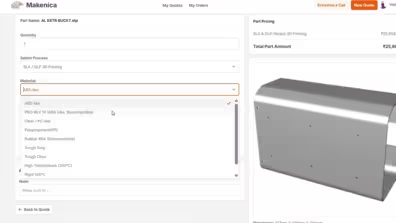

How Makenica Works?

Transform your ideas into 3D printed parts—faster than ever. Upload your CAD file for instant quoting, rapid production, and doorstep delivery with end-to-end quality control.

1. Upload your CAD

One Click Login to upload your CAD files (STL, STP, OBJ)

2. Get Instant Quotation

Get real-time instant pricing based on your CAD.

3. Start 3D Printing

Your parts move into production within hours.

4. Quality Control

Quality Control Team verifies accuracy & consistency.

5. Ready for Delivery

Shipped using top courier partners to ensure safe delivery.

Frequent questions & answers

Answers to questions about our 3d printing services and quotation platform.