Rapid Prototyping For Medical

Get ultra-durable, skin-safe, bio-compatible certified 3D printing services for med-tech prototypes, enclosures, prosthetics, dental, implants, lens assembly.

Your CAD uploads are protected as per ISO/IEC 27001

Medical Prototyping Engineering Lifecycle: From Concept to Production-Ready Excellence

Our 5-Stage Journey from Specification to Certified Production.

Stage 1

Product Definition & Specification

For medical 3D printing, this step defines project requirements and feasibility—capturing functional needs, design boundaries, and compliance standards in PRDs and technical documentation.

Stage 2

Design & Development

From conceptual design to detailed engineering, this step outputs precise 3D CAD models, GD&T drawings, and verified designs via FEA, DFM/DFA, and tolerance stack‑up methods.

Stage 3

Prototyping & Design Verification

Bio-compatible prototypes are fabricated using advanced 3D printing methods—SLA, SLS, MJF, and DLP—and validated via Functional Testing, ESS, and FMEA for medical‑grade safety.

Stage 4

Process Engineering & Pre-Production

Covers SOP development for medical 3D printing, orientation accuracy, and build optimization—backed by pilot runs, process capability analysis, FDA, and supply chain verification.

Stage 5

Production & Quality Assurance

From SPC and assembly line balancing to in‑process inspection, full‑scale 3D printing production ends with stringent final QC—CMM, NDT, and conformance documentation.

Our 3D Printing Services

Experience India's widest and largest 3D printing services, with free online instant quotations.

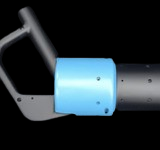

SLA 3D Printing Services

SLA - Stereolithography

SLA 3D printing offers fast and precise parts with smooth surface finishes and exceptional detail, making it ideal for rapid prototyping and showcase models.

Materials: ABS, Clear PC-Like

Max Print Size: up to 1200mm

Delivery within 24 Hours

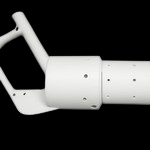

SLS 3D PRINTING SERVICES

SLS - Selective Laser Sintering

SLS 3D printing delivers nylon-grade parts, making it ideal for rapid prototyping, end-use functional models and low-batch production.

Materials: Nylon PA12, PA12 + Glass Filled

Max Print Size: up to 450mm

Delivery within 3 days

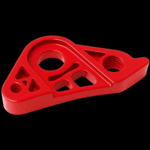

DLP 3D PRINTING SERVICES

DLP - Digital Light Processing

When design becomes challenging, 3D Systems Figure 4 delivers ultra-thin production grade parts within hours.

Materials: Pro-Black 10, Rubber65A

Max Print Size: up to 200mm

Delivery within hours

Product Design & 3D Modeling

3D Designing & Modeling

Our expert CAD engineers turn your concepts into precise, production‑ready designs—bringing your ideas to life with accuracy and speed.

Simple Part Modifications

Reverse Engineering Services

Designing products from scratch

Painting and Finishing

In-house Post Process

Get exceptional finishes and precise RAL color matching, ensuring your parts look exactly as you imagined.

Automotive grade paint booth facility

Finishes: Matte, Glossy, SoftTouch

Delivery within 48 Hours

Finishing Options for Medical 3D Printing

Along with our 3D printing services, we have an integrated paint booth that allows us to deliver stunning finishes and precise RAL colour matching with low RA value.

| Photo | Material Name | Max. Print Size | Layer Thickness | Tolerance |

|---|---|---|---|---|

| SLA - ABS-Like | 1200 x 1000 x 650mm | 100 micron | ± 0.1mm to 0.2mm |

| SLA - ABS-Like | 1200 x 1000 x 650mm | 100 micron | ± 0.2mm to 0.25mm |

| SLA - PC-Like | 700 x 600 x 450mm | 100 micron | ± 0.1mm to 0.2mm |

| SLA - PC-Like | 700 x 600 x 450mm | 100 micros | ± 0.2mm to 0.25mm |

| SLS - Nylon PA12 | 450 x 450 x 450mm | 100 micron | ± 0.25% (min: ±0.25mm) |

| SLS - Nylon PA12 | 450 x 450 x 450mm | 100 micron | ± 0.25% (min: ±0.25mm) |

| SLS - Nylon PA12 + Glass Filled | 450 x 450 x 450mm | 100 micron | ± 0.25% (min: ±0.25mm) |

| Figure 4 DLP - PRO-BLK 10 | 124.8 x 70.2 x 196 mm | 30 micron | ±0.10 mm to 1% of actual |

| Figure 4 DLP - PRO-BLK 10 | 124.8 x 70.2 x 196 mm | 30 micron | ±0.10 mm to 1% of actual |

| Figure 4 DLP - RUBBER-65A BLK | 124.8 x 70.2 x 196 mm | 30 micron | ±0.10 mm to 1% of actual |

| Figure 4 DLP - HI TEMP 300-AMB | 124.8 x 70.2 x 196 mm | 30 micron | ±0.10 mm to 1% of actual |

Join 4600+ Happy Customers

Our delighted customers and their first hand experience with our 3D printing services.

Why Medical Companies Choose Makenica?

Medical Companies choose Makenica for smooth, precise, and bio-compatible 3D printing output services backed by best-in-class 3D printers.

-

Part Inspection Reports

Our 3D printed parts meet specs, verified time and again through inspection reports.

-

Enforceable NDA & Confidentiality

Every design you share with us, are covered by ISO 27001 data-security protocols.

-

Meeting Critical Deadlines

Parts at 1am? No problem. Our services include priority 3D printing & post processing.

Meet Makenica Console Most Advanced Quoting Engine

Get instant, accurate 3D printing quotes with smart DFM checks, material options, and precise lead times—streamlining your workflow from upload to order.

3D Printing Quotations, In a Blink

Our online 3D printing console allows you to upload CAD files, get free quotation within seconds. You can further tweak material, and print settings to get the perfect output for your product.

Our Origin: Made from Failure, Built for Makers

We started as a small hardware team with a big dream—and ran straight into manufacturing walls: missed tolerances, blown timelines, and costs we couldn’t control. That failure hurt, but it lit a fire. We promised to make manufacturing simpler, faster, and fairer for every maker who dares to build—and we put that promise in our name: Make(nica).

Frequent questions & answers

Answers to questions about medical 3D printing services & our quotation platform